Sikafloor® DecoDur EB-26 Quartz ESD

Conductive slip resistant epoxy flooring system

Sikafloor® DecoDur EB-26 Quartz ESD is a coloured, conductive resin based epoxy flooring system. It provides a hard wearing, seamless, low maintenance, slip resistant finish.

- Provides reliable and long lasting ESD protection

- Functional finish with outstanding appearance

- Decorative design

- Textured gloss finish

- High mechanical resistance

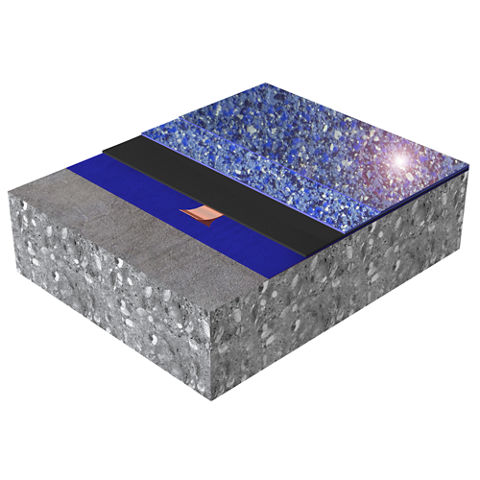

System Structure

1

Primer

2

Grounding connection

3

Conductive primer

Usage

The system can be used in industrial buildings such as:- Airports

- Pharmaceutical facilities

- Electronic facilities and data centres

- Manufacturing facilities and workshops

- Food and Beverage facilities

- The System may only be used for interior applications.

- The System may only be used by experienced professionals.

Advantages

- Provides reliable and long lasting ESD protection

- Functional finish with outstanding appearance

- Decorative design

- Textured gloss finish

- High mechanical resistance

Colour

| Iceberg:

|

| Noblesse:

|

| Granit:

|

Note: When the system is exposed to direct sunlight, there may be some discolouration and colour variation. This has no influence on the function and performance of the floor finish.

Appearance

| Final floor appearance | Glossy orange peel |

System Details

APPROVALS / STANDARDS

- Fire classification report, EN 13501-1, Ghent University, Report No. CR 21-0127-01

- Test of floor, IEC 61340, RISE Institute, Report No. P105613 A, rev 1

- Approval for ESD protective products, IEC 61340-5-1, RISE Institute, No. ESD-20-0022, rev 1

- Slip resistance, DIN 51130, Roxeler, Certificate No. 020017-21-1

System Structure

Sikafloor® DecoDur EB-26 Quartz ESD (~2–3 mm)

| Layer | Product |

| 1. Primer or scratch coat | Sikafloor®-150 Sikafloor®-151 Sikafloor®-156 Sikafloor®-161 Sikafloor®-144 Sikafloor®-701 |

| Levelling (if required) | Sikafloor®-150 Sikafloor®-151 Sikafloor®-156 Sikafloor®-161 levelling mortar |

| 2. Conductive primer + earthing connection | Sikafloor®-220 W Conductive + |

| 3. Conductive wearing layer | Sikafloor®-169 ESD Broadcast in excess Sika® PU Quartz |

| 4. Top coat | Sikafloor®-169 ESD |

Composition

Epoxy

Nominal thickness

~2 mm to 3 mm

Reaction to Fire

| Class Bfl-s1 | (EN 13501-1) |

Thermal Resistance

| Short-term, maximum 7 days | +60 °C |

IMPORTANT

No simultaneous mechanical and chemical strain

While the system is exposed to temperatures up to +60 °C, do not also subject it to chemical and/or mechanical strain, as it may cause damage to the system.

Skid / Slip Resistance

| R 11; V 4 | (DIN 51130) |

| Sliding friction coefficient µ = 0.52 | (DIN 51131) |

Electrostatic Behaviour

| Resistance to ground | RG < 109 Ω |

| Typical average resistance to ground | RG ≤ 105 Ω to 106 Ω |

| Body voltage generation | < 100 V |

Note: Measurement results can be affected by ESD clothing, ambient conditions, measurement equipment, cleanliness of the floor and the test personnel.

ESD MEASUREMENT CONDITIONS AND SPECIFICATIONS

All measurement values for the system stated in the System Data Sheet (except those referring to proof statements) were measured using the following equipment and ambient conditions:

| Condition or Equipment | Specification |

| Size of ESD-footwear | 42 (EU) (UK: 8; US: 8.5) |

| Test person weight | 90 kg |

| Ambient conditions | +23 °C / 50 % |

| Measuring device for measuring resistance to ground | Metriso 2000 or 3000 (Warmbier) or comparable |

| Surface resistance probe | Carbon Rubber electrode. Weight: 2.50 kg |

| Rubber pad hardness | Shore A 60 (±10) |

| Measuring device for measuring body voltage generation | Walking Test Kit WT 5000 (Warmbier) or comparable |

Application

Ambient Air Temperature

| Minimum | +10 °C |

| Maximum | +30 °C |

Relative Air Humidity

80 % r.h. max.

Dew Point

Beware of condensation. The substrate and uncured applied product must be at least +3 °C above dew point to reduce the risk of condensation or blooming on the surface of the applied product. Low temperatures and high humidity conditions increase the probability of blooming.

Substrate Temperature

| Minimum | +10 °C |

| Maximum | +30 °C |

Substrate Moisture Content

< 4 % parts by weight (Sika® Tramex moisture meter)

No rising moisture (ASTM D4263, polyethylene sheet)

The substrate must be visibly dry with no standing water.

Waiting Time / Overcoating

Conductive decorative slip resistant epoxy quartz finish flooring system

Before applying Sikafloor®-220 W Conductive on Sikafloor®-150/ -151/ -156/ -161 allow:

| Substrate temperature | Minimum | Maximum |

| +10 °C | ~24 hours | ~4 days |

| +20 °C | ~12 hours | ~48 hours |

| +30 °C | ~8 hours | ~24 hours |

Before applying Sikafloor®-169 ESD on Sikafloor®-220 W Conductive allow:

| Substrate temperature | Minimum | Maximum |

| +10 °C | ~26 hours | ~7 days |

| +20 °C | ~17 hours | ~5 days |

| +30 °C | ~12 hours | ~4 days |

Before applying Sikafloor®-169 ESD on Sika PU Quartz Conductive 0.3–0.8 and Sikafloor®-169 ESD allow:

| Substrate temperature | Minimum | Maximum |

| +10 °C | ~45 hours | ~4 days |

| +20 °C | ~36 hours | ~3 days |

| +30 °C | ~24 hours | ~48 hours |

Note: Times are approximate and will be affected by changing ambient conditions particularly temperature and relative humidity.

Applied Product Ready for Use

Conductive decorative slip resistant epoxy quartz finish flooring system

| Temperature | Foot traffic | Light traffic | Full cure |

| +10 °C | ~36 hours | ~5 days | ~10 days |

| +20 °C | ~12 hours | ~3 days | ~7 days |

| +30 °C | ~8 hours | ~48 hours | ~5 days |

Consumption

Conductive decorative slip resistant epoxy quartz finish flooring system

| Layer | Product | Consumption |

| Primer or scratch coat | 1 × Sikafloor®-150 Sikafloor®-151 Sikafloor®-156 Sikafloor®-161 Sikafloor®-144 Sikafloor®-701 | ~0.3 kg/m² to 0.5 kg/m² |

| Levelling (if required) | Sikafloor®-150 Sikafloor®-151 Sikafloor®-156 Sikafloor®-161 | Refer to the individual Product Data Sheet |

| Conductive primer + | Sikafloor®-220 W | 1 × 0.08–0.10 kg/m² 1 earthing point per ~200–300 m². |

| Conductive wearing layer | 1 × Sikafloor®-169 ESD | 1 × 0.5 kg/m² |

| Broadcast | Broadcast in excess | ~3.5 kg/m² |

| Top coat | 1 × Sikafloor®-169 ESD | 1 × ~0.5 kg/m² |

Note: These figures are theoretical and do not allow for any additional material due to surface porosity, surface profile, variations in level, wastage or any other variations. Apply product to a test area to calculate the exact consumption for the specific substrate conditions and proposed application equipment.

APPLICATION

INSTALLATION OF EARTHING POINTS

Refer to Sika Method Statement: Mixing & Application of Flooring Systems.

Number of earthing connections per room: Minimum of 2 earthing connections. The optimum number of earthing connections depends on the local conditions and must be specified on drawings or other contract documentation.

ESD CONDUCTIVITY MEASUREMENTS

Recommended number of conductivity measurements is specified in the following table:

| Ready applied area | Number of measurements |

| < 10 m² | 6 |

| ≥ 10 m² and < 100 m² | 10 to 20 |

| ≥ 100 m² and < 1000 m² | 50 |

| ≥ 1000 m² and < 5000 m² | 100 |

If the measurements yield values that are outside of the agreed specification, follow these steps:

- Carry out one additional measurement within a radius of approximately 30 cm around the original measuring point.

- If the value of the new measurement meets the agreed specification, the original measurement can be disregarded. If the value of the new measurement does not meet the agreed specification, you may repeat the measurement described above, until the fulfilment of the requirements have been verified. If the requirements cannot be verified, contact Sika technical services.